The Brazilian automotive industry, coordinated by Anfavea, includes automakers with factories in Brazil. In 2021, annual production exceeded 2.2 million vehicles, making it the 8th largest in the world.

Brazil is home to major global automotive companies like BMW, BYD, Chery, Fiat, Ford, Geely, Honda, Hyundai, JAC Motors, Kia, Land Rover, Lexus, Mercedes-Benz, Mitsubishi, Nissan, Renault, Stellantis, Subaru, Toyota, Volkswagen, and Volvo Trucks.

The Brazilian automotive industry began with Henry Ford in 1919, followed by General Motors in 1926. The Romi-Isetta, Toyota Bandeirante, Volkswagen Type 2, and Tupi were produced in 1956. In the late 1950s, Chevrolet, Ford, and GM dominated the market until the mid-1990s when it was opened to imports.

In the 1990s, more auto companies settled and opened factories in Brazil. The Brazilian auto industry has grown rapidly, attracting investments from global automakers. In 2007, production grew 14%, reaching over 4 million vehicles. The Inovar-Auto Program, approved in 2012, aimed to encourage fuel-efficient vehicles and investment in the industry but faced criticism for protectionism.

Brazilian automotive assembly plants, producing thousands of cars daily, prioritize safety through the use of energy-saving emergency drivers. In 2020, vehicle production dropped to 1957 levels due to COVID-19. In 2021, GWM bought Mercedes-Benz, and in 2022, GWM opened a factory for electric SUVs and pickup trucks. The Brazilian automotive sector plans hybrid ethanol cars due to local biofuel production and clean energy.

What Are Energy-Saving Emergency Drivers?

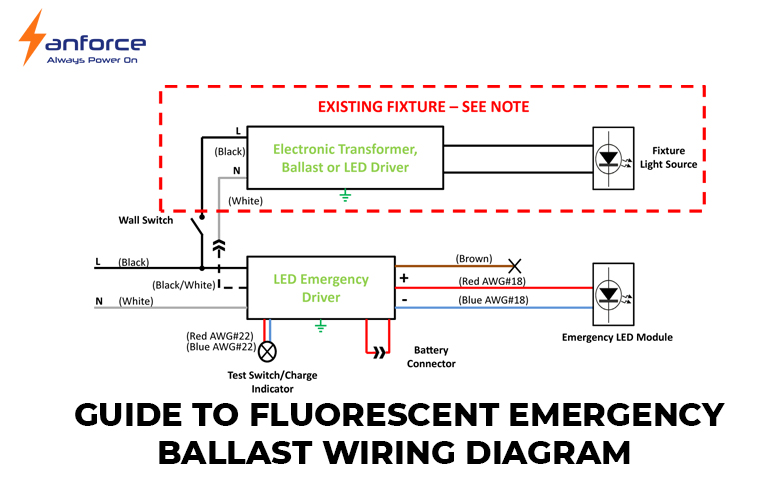

Energy-saving emergency drivers are crucial devices installed in facilities like automotive assembly plants to provide backup power during emergencies, ensuring continuous operation of essential systems in case of power outages or natural disasters. It provides backup power during emergencies, instantly activating when the main power supply fails. They ensure essential systems, such as emergency lights and alarms, operate safely and prevent disruptions during unforeseen events.

Importance Of Safety Standards In Brazilian Automotive Plants

Safety standards in Brazilian automotive plants are crucial for worker protection, regulatory compliance, product quality, productivity, reputation, and cost savings, ensuring the industry’s success and sustainability. Safety standards in Brazilian automotive plants are crucial for various reasons. Here are the importance of safety standards in Brazilian automotive plants.

- Worker safety standards ensure workers’ protection from accidents and injuries by mandating PPE use, safe operating procedures, and regular training for handling heavy machinery and hazardous materials.

- Brazil’s automotive plants must adhere to safety standards to avoid fines, lawsuits, or plant closure, demonstrating their commitment to worker safety and upholding the law.

- Safety standards and quality control measures are crucial in maintaining product quality by preventing accidents and defects, thereby ensuring the production of reliable and safe vehicles for consumers.

- Prioritizing safety in the workplace boosts employee morale and productivity, as it creates a positive work environment that encourages focus and contributes to the plant’s success.

- Adhering to safety standards in automotive plants and their parent companies can strengthen their reputation, build trust with consumers, investors, and regulatory authorities.

- Implementing safety standards can lead to long-term cost savings, including reduced medical expenses, worker compensation claims, equipment damage, and downtime, resulting in uninterrupted production and higher profitability.

How Energy-Saving Emergency Drivers Enhance Safety?

Energy-saving emergency drivers are crucial in automotive assembly plants for ensuring safety, efficient emergency response, and preventing accidents and operational disruptions by providing continuous power supply to critical systems. Energy-saving emergency drivers are enhancing safety in various ways.

- Energy-saving emergency drivers maintain essential systems, such as lights, alarms, and machinery, during power outages or emergencies, preventing accidents and enabling safe evacuation procedures.

- Emergency lights are crucial for guiding people during evacuations, ensuring visibility and reducing accidents. Energy-saving drivers maintain these lights even when power supply fails.

- Critical systems in automotive assembly plants require continuous power for proper functioning, and energy-saving emergency drivers ensure these systems remain operational during emergencies, enabling effective worker response and risk mitigation.

- Energy-saving emergency drivers provide temporary power to computer systems in automotive plants, preventing data loss and disruptions caused by power outages.

- Energy-saving emergency drivers assist automotive plants in complying with safety regulations by providing a reliable backup power source, ensuring plant operation and safety during unforeseen emergencies.

Implementation In Brazilian Automotive Plants

Brazilian automotive plants are implementing energy-saving emergency drivers through a structured approach, ensuring reliable operation, safety, and efficiency in their operations.

- Plant managers evaluate the plant’s emergency backup power needs, identifying critical systems like lighting and machinery, to determine the necessary capacity for emergency drivers.

- The selection of suitable energy-saving emergency drivers is based on assessment, ensuring they meet regulatory standards and are compatible with the plant’s infrastructure.

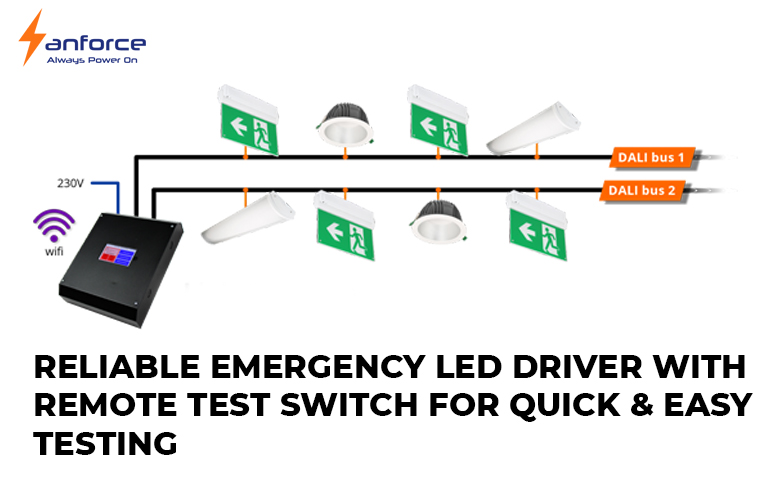

- Skilled technicians install emergency drivers strategically within the plant, ensuring proper integration with existing electrical systems, wiring them, and connecting them to necessary equipment.

- Emergency drivers undergo rigorous testing to ensure their functionality, with technicians simulating power outages and emergencies to verify their reliability and effectiveness in providing backup power.

- Plant staff undergo training on emergency drivers’ operation and maintenance, including activation and routine checks to ensure proper functioning during emergencies.

- The company maintains comprehensive documentation, including installation records and test reports, to ensure regulatory compliance and serves as a reference for audits and inspections.

- Regular maintenance is essential for emergency drivers, involving inspections, battery checks, and software updates to prevent malfunctions and ensure readiness for emergencies.

- Plant management continuously assesses emergency drivers’ performance, using feedback from testing and maintenance to identify areas for improvement and implement necessary changes.

Benefits Of Using Energy-Saving Emergency Drivers In Brazilian Automotive Plants

Brazilian automotive plants are implementing energy-saving emergency drivers, resulting in improved safety, reduced downtime, enhanced efficiency, regulatory compliance, equipment protection, reputation enhancement, and increased employee morale and productivity. Here are the benefits of using energy-saving emergency drivers in Brazilian automotive plants.

- Energy-saving emergency drivers ensure continuous power supply to critical systems, maintaining a safe working environment and facilitating efficient evacuation procedures during power outages or emergencies.

- Energy-saving emergency drivers in automotive plants reduce downtime during power outages, allowing essential systems to remain operational, reducing financial losses associated with downtime.

- These drivers optimize energy usage, ensuring power distribution during emergencies, reducing operational costs, and contributing to sustainability efforts in automotive plants.

- Energy-saving emergency drivers assist automotive plants in complying with safety regulations and backup power systems, ensuring legal compliance and mitigating penalties or fines for non-compliance.

- Energy-saving emergency drivers provide continuous power supply to protect critical machinery and computer systems from damage or data loss during power outages, preventing costly repairs and ensuring production process integrity.

- Brazilian automotive plants can improve their reputation by prioritizing safety and implementing reliable backup power systems, thereby enhancing their efficiency and market perception.

- A secure, energy-efficient working environment with emergency drivers can boost employee morale and productivity by ensuring the plant can effectively handle emergencies.

Read more:- Innovative Emergency Lighting Technology for Swedish Pharmaceutical Factories

Conclusion

In conclusion, Brazilian automotive plants prioritize safety standards for workers’ well-being and operational efficiency. Energy-saving emergency drivers provide backup power during emergencies, enhancing safety, facilitating evacuations, minimizing downtime, protecting equipment, and complying with regulations. This commitment to safety, efficiency, and employee welfare contributes to industry success and sustainability.

FAQs

-

What are energy-saving emergency drivers?

Energy-saving emergency drivers are devices that provide backup power during emergencies in Brazilian automotive assembly plants.

-

Why are energy-saving emergency drivers important?

They are important because they ensure continuous power supply to critical systems like emergency lighting and alarms during power outages or emergencies, enhancing safety in the plant.

-

How do energy-saving emergency drivers work?

These drivers are equipped with batteries or alternative power sources that automatically activate when the main power supply fails, ensuring that essential systems remain operational.

-

What are the benefits of using energy-saving emergency drivers?

The benefits include enhanced safety for workers, minimized downtime, improved efficiency, compliance with regulations, protection of equipment and data, enhanced reputation, and increased employee morale and productivity.

- How are energy-saving emergency drivers implemented in Brazilian automotive plants?

Implementation involves assessing needs, selecting suitable drivers, installing and integrating them into the plant’s infrastructure, testing and validating their functionality, providing personnel training, documenting and complying with regulations, conducting regular maintenance, and continuously seeking improvement.

- Are energy-saving emergency drivers mandatory in Brazilian automotive plants?

While not explicitly mandatory, they are highly recommended and often required to comply with safety regulations and standards.

- How do energy-saving emergency drivers contribute to sustainability?

By optimizing energy usage and reducing downtime, energy-saving emergency drivers help automotive plants operate more efficiently, thereby contributing to sustainability efforts and minimizing environmental impact.